carrageenan production process

Carrageenan which is an extract from raw diced seaweeds serves as the main ingredient for cosmetics medicine and food. It consists in broth preparation pH adjustment 1422 by mass and sterilization followed by yeast fermentation.

Pdf Extraction And Isolation Of Kappa Carrageenan From Red Seaweeds Semantic Scholar

This enhances consumers experience through reduced aftertaste and reflux.

. No matter which line they all semi-auto or fully automatic jelly making line which controlled by PLC. The beer brewing process. Suitable for vegetarians and vegans.

The FDA Code of Federal Regulations CFR 2015 Frye and Kilara 2016 standard of identity for yogurt low-fat and nonfat yogurt calls for a minimum of 825 nonfat milk solids SNF in the fermented mix before the addition of bulky flavorsIn a typical nonfat low-fat or full-fat yogurt formulation the total milk serum solids or solids-not-fat content of yogurt mix. We have 40 years of expertise in manufacturing top- notch industry-specific Agar-Agar products of various grades and forms Spreadable type Agar Agar Carrageenan Agarose Gums such as Gellan gum Xanthan gum Guar gum and Sodium. Wort production and beer fermentation.

Specifications are necessary for. Handbook of food products manufacturing 1st edn 2007. Being the largest manufacturer and exporter of Agar Agar in India we ensure the quality is never compromised in any of our products.

The process developed by Sachdeva et al. Involved standardization and heating of milk followed by UF. Carrageenan is a common food additive thats made from seaweed.

So 2-3 Workers can handle the complete jelly candy production line. The Melle-Boinot process is the typical process for bioethanol production in batch fermentation. The sugar used for xanthan gum production may come from wheat corn soy or dairy.

About the Societies. The goal is to be able to process seaweeds chips that can be sold as raw. Fattening practices shall be reversible at any stage of the rearing process.

This pathway either needs to be eliminated to maximize hydrogen production and simplify the process or it needs to be taken advantage of by the integrated multi-step processes described below. This does not include jelly candy packaging work. Sizing is used for oil-based surface preparation for gilding sometimes called mordant in this context.

Although your bodys collagen production does affect the health of your skin joints and bones dietary collagen consumption cant help counteract or. Sizing or size is a substance that is applied to or incorporated into other materialsespecially papers and textilesto act as a protective filler or glazeSizing is used in papermaking and textile manufacturing to change the absorption and wear characteristics of those materials. In addition their production requires subsequent wastewater treatment which adds cost and complexity to the system.

Health Benefits of Plain Gelatin. The typical bands of a carrageenan spectrum are also shown Figure 8b because many of its important uses are similar to those of agar and the spectra are useful for distinguishing the two. Enteric capsules enable delayed release of the product into the intestine.

The Association for Academic Surgery is widely recognized as an inclusive surgical organization. Gelatine agar calcium alginate κ-carrageenan chitosan and polyacrylamide iii mechanical separation behind a. Instead they can consume plant-based alternatives like agar-agar pectin or carrageenan.

Likewise it is very important to assure the absence of residues of reagents used in the agarose production process. Full PDF Package Download Full PDF Package. Organic-production holdings may establish written cooperation agreements exclusively with other holdings and enterprises which comply with the organic production rules with the intention of spreading surplus manure from organic production.

The final capacity of jelly candy production will depend on each jelly candy weight. This website uses cookies to help provide you with the best possible online experience. Single process production reduces time cost and risk by eliminating additional coatings.

8 Foods You Thought Were Vegan or Vegetarian But Arent. The program needs facilities to improve the production and income of seaweed farmers such as processing plants and storage facilities. A short summary of.

The impetus of the membership remains research-based academic surgery and to promote the shared vision of research and academic pursuits through the exchange of ideas between senior surgical residents junior faculty and established. An additional consideration is the sugar source used in the fermentation process. Please read our Terms Conditions and Privacy Policy for information about.

Use of modern mechanized process offers advantages of uniform quality improved shelf life increased yield and a nutritionally better product. Carrageenan and allergen free with a better thermal stability. The concentrated mass which had about 40 per cent total solids was cold acidified to get the.

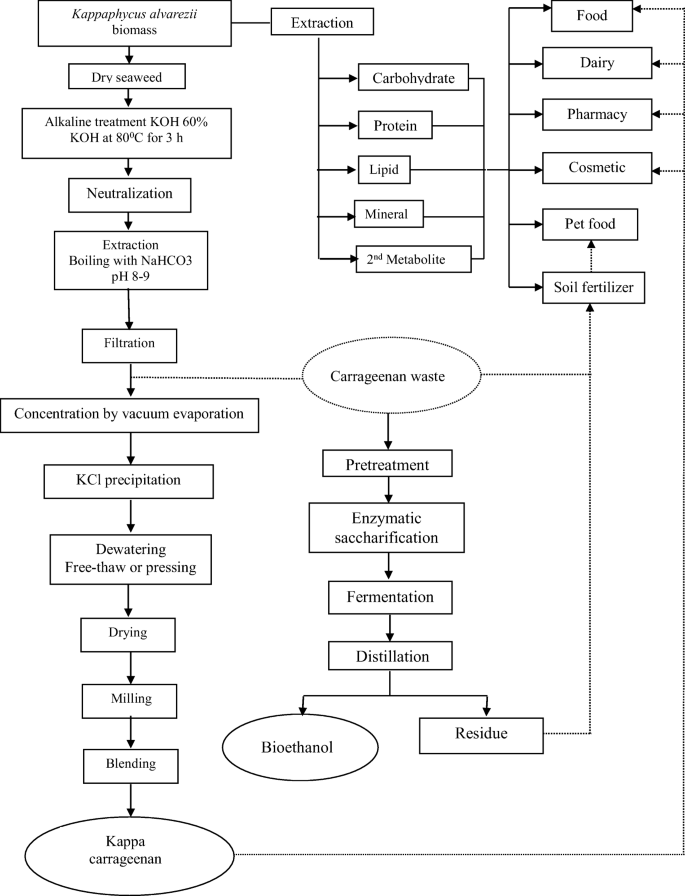

Sequential Acid And Enzymatic Hydrolysis Of Carrageenan Solid Waste For Bioethanol Production A Biorefinery Approach Springerlink

Process Flow Sheet For Preparation Of Semi Refined Carrageenan Download Scientific Diagram

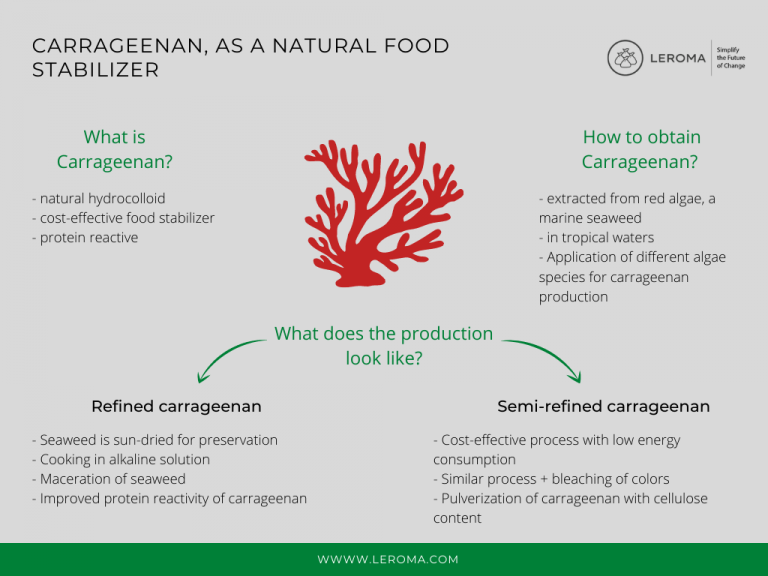

Leroma Carrageenan A Natural And Versatile Food Stabilizer

Carrageenan An Overview Sciencedirect Topics

Seaplant Net The South East Asia Seaplant Network

Proposed Carrageenan Biosynthesis Pathways Pathway 1 Download Scientific Diagram

5 Flow Chart Of Semi Refi Ned Carrageenan Production Where The Download Scientific Diagram

Carrageenan Manufacturing Process Flow Chart Re Produced From Download Scientific Diagram

Carrageenan Manufacturing Process Flow Chart Re Produced From Download Scientific Diagram

5 Flow Chart Of Semi Refi Ned Carrageenan Production Where The Download Scientific Diagram

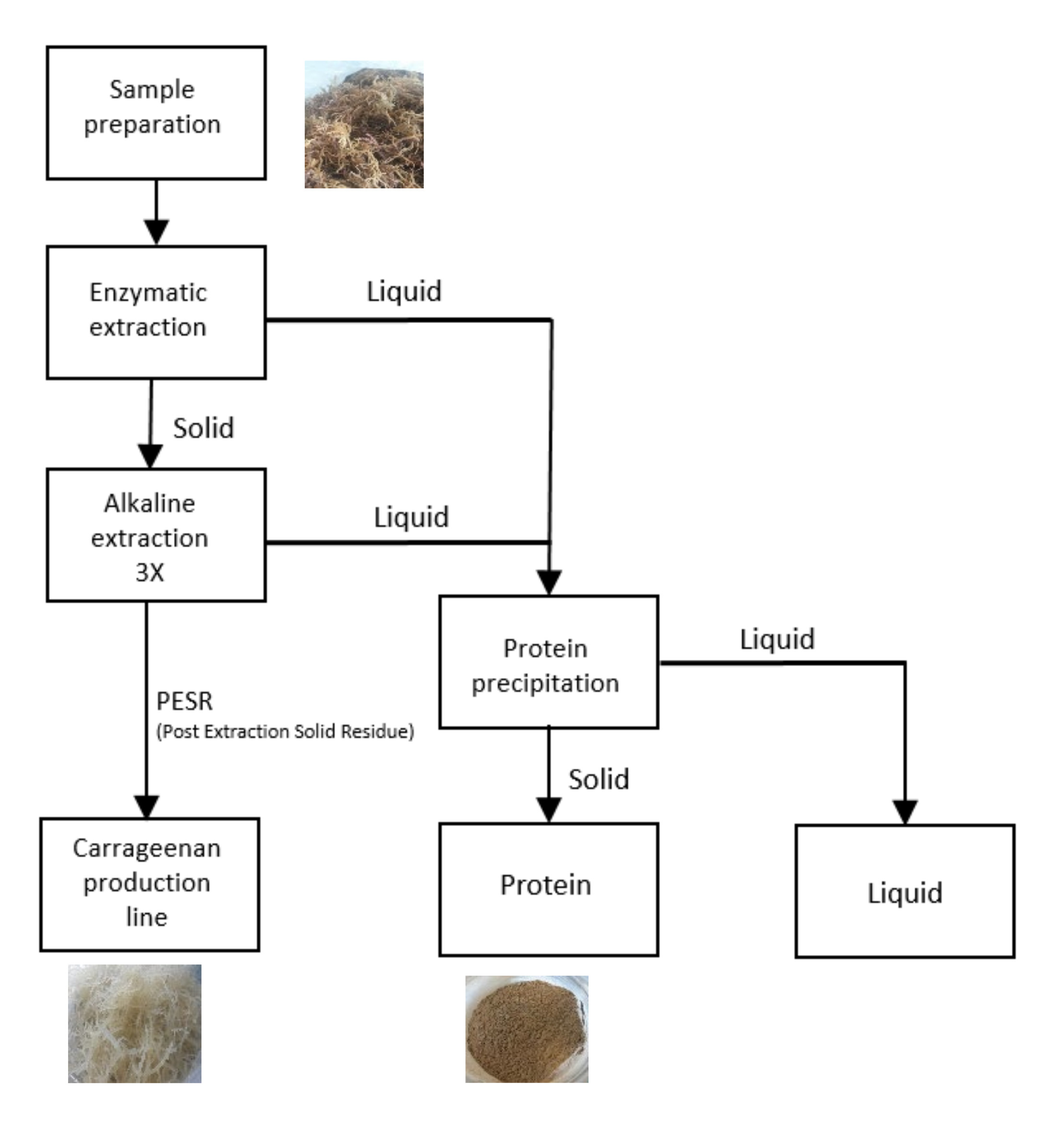

Foods Free Full Text Multi Extraction And Quality Of Protein And Carrageenan From Commercial Spinosum Eucheuma Denticulatum Html

Carrageenan 101 Mcpi Carrageenan For The World

Lecture Xviii Charged Ps S Carrageenan Agar Ppt Download

Characteristics Of Lactose Free Frozen Yogurt With K Carrageenan And Corn Starch As Stabilizers Journal Of Dairy Science

Re Evaluation Of Carrageenan E 407 And Processed Eucheuma Seaweed E 407a As Food Additives 2018 Efsa Journal Wiley Online Library

Comments

Post a Comment